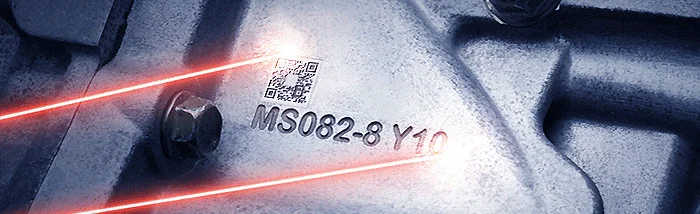

Han's Laser has more than 100 different models in the field of laser marking, and rich product lines, including various models suitable for various marking applications metal and non-metal marking, PCB marking, IC marking, and semiconductor wafer marking.

As non-contact processing, laser cutting can be applied to a variety of materials. Han's Laser independently developed various types of fiber laser cutting machines, CO2 laser cutting machines, YAG laser cutting machines and other series of products.

With continuous R&D investment in the field of laser welding, Han's Laser has independently developed full types of laser sources (YAG, fiber, semiconductor), widely used in hardware welding, jewelry spot welding, mold repair welding, plastic welding,

Through our own technological development and external technology absorption, Han's Laser has been highly professional in automation applications and has accumulated rich experience. We can customize project plans according to the specific customer needs.

In recent years, laser inspection has more and more applications in 3C consumer electronics and automotive industries. Based on our deep R&D strength in the laser industry, and rich experience in automation integration, Han's Laser has the strong capacity

Wire bonders are vital for semiconductor packaging. Featuring nanometer motion, ultrasonic drives, and AI vision, they deliver high-speed, stable, and ultra-reliable connections for advanced packaging and smart manufacturing.

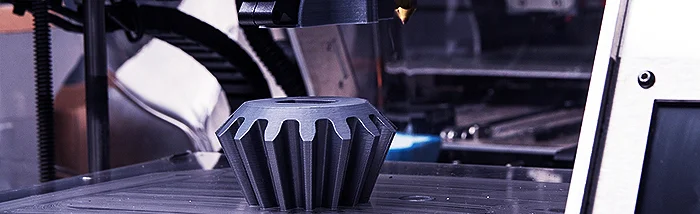

3D printers mostly use fiber lasers as energy sources, equipped with high-precision scanning galvanometers, mature slicing and path planning software, etc., achieving high-speed scanning and production, which is safe, reliable, stable, and highly precise.

Han's Motor is a leader in direct drive systems, providing efficient, tailored solutions through close collaboration to solve unique client challenges and enhance their productivity, reliability, and performance.