PCB Industry

Lasers bring precision and versatility to PCB manufacturing. They enable permanent, high-contrast marking for traceability. Laser welding creates strong, reliable connections with minimal heat input. For cutting, lasers offer stress-free, burr-free depaneling of complex shapes with no tool wear. In dispensing, they provide selective curing for strong, localized adhesion. This non-contact technology is key for high-density, miniaturized electronics, improving quality and yield while reducing waste and operational costs.

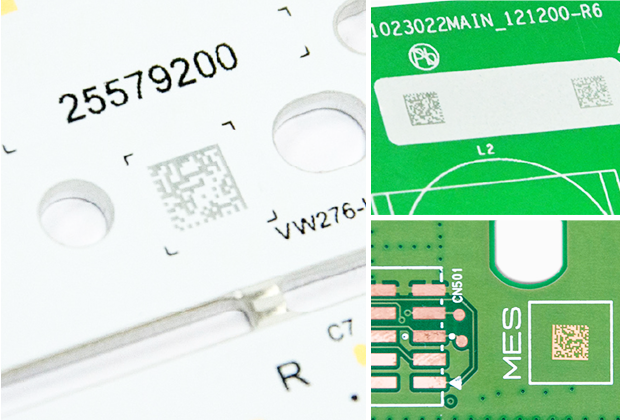

PCB Marking

1. Suitable for marking traceability information such as barcode, QR code, and characters on the hard copper plate layer of PCBs in the fields of mobile phones, wearable devices, and automotive electronics.

2. Ultraviolet、Green、Infrared、CO2 laser is suitable.

3. Processing method could be single-faced marking, double-faced(built-in flap) marking, and double-faced(double laser heads) marking.

2. Ultraviolet、Green、Infrared、CO2 laser is suitable.

3. Processing method could be single-faced marking, double-faced(built-in flap) marking, and double-faced(double laser heads) marking.

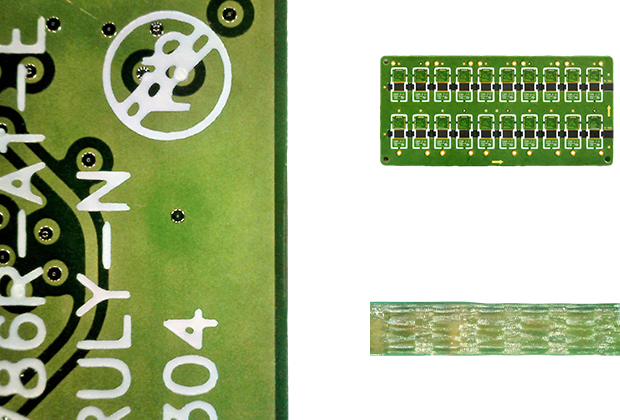

PCB Cutting

1. Non-contact process: Eliminates mechanical stress and deformation.

2. Ideal for any shape: Produces no dust, a narrow kerf, and a small heat-affected zone.

3. Full imported vision system: Ensures high precision for effectively processing high-density, high-integration PCBs.

2. Ideal for any shape: Produces no dust, a narrow kerf, and a small heat-affected zone.

3. Full imported vision system: Ensures high precision for effectively processing high-density, high-integration PCBs.

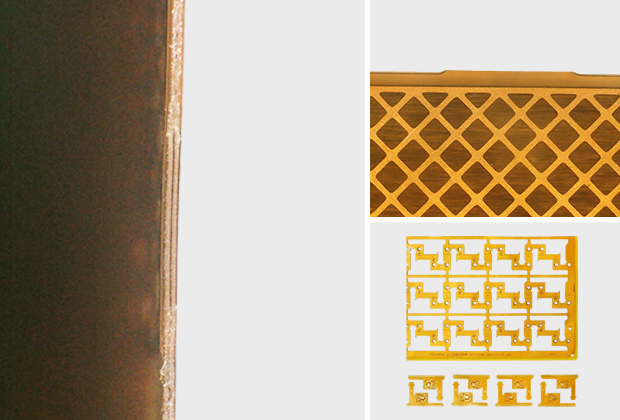

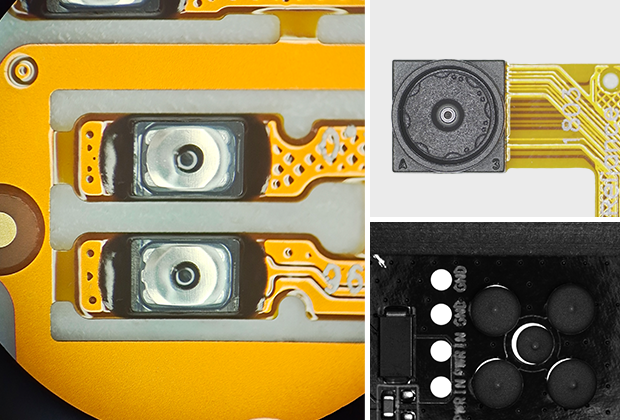

FPCA Cutting

1. Non-contact process: Eliminates mechanical stress and deformation.

2. Ideal for any shape: Produces no dust, a narrow kerf, and a small heat-affected zone.

3. Full imported vision system: Ensures high precision for effectively processing high-density, high-integration PCBs.

2. Ideal for any shape: Produces no dust, a narrow kerf, and a small heat-affected zone.

3. Full imported vision system: Ensures high precision for effectively processing high-density, high-integration PCBs.

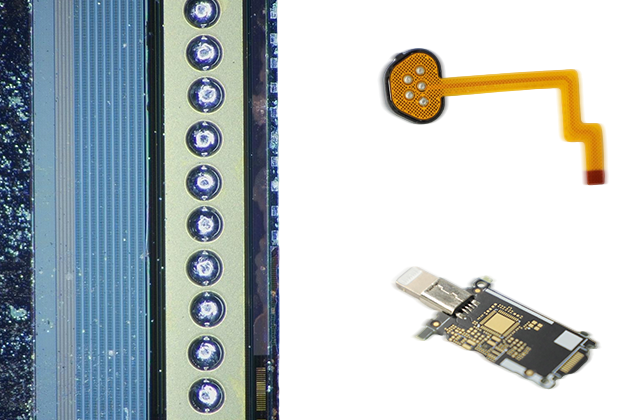

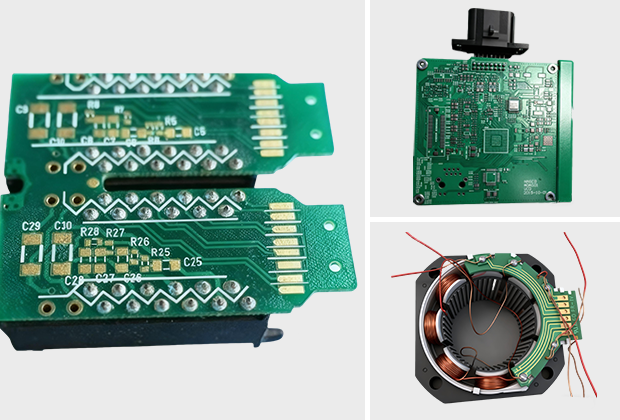

Solder Ball Welding

1. Can be applied to solder ball welding of precision structural components in industries such as 3C electronics, WATCH, PAD, CCM modules, semiconductor wafers, etc.

2. Adopting advanced fiber laser and highly integrated with industrial control system in the workbench cabinet, coupled with ball planting mechanism to achieve synchronization between tin balls and laser welding, achieving efficient automatic welding and greatly improving production efficiency.

3. It can meet the soldering requirements of precision components such as camera modules, VCM enameled coil modules, and contact basin frames, and has the ability of special applications.

2. Adopting advanced fiber laser and highly integrated with industrial control system in the workbench cabinet, coupled with ball planting mechanism to achieve synchronization between tin balls and laser welding, achieving efficient automatic welding and greatly improving production efficiency.

3. It can meet the soldering requirements of precision components such as camera modules, VCM enameled coil modules, and contact basin frames, and has the ability of special applications.

Solder-Wire Welding

1. The technical solution uses semiconductor lasers with low peak power to meet the welding requirements of low melting point solder materials such as soldering/brazing; Non-contact heat source, small light spot, small heat affected area, can minimize damage around the solder joint to the greatest extent possible.

2. In response to the differences in energy requirements for product solder joints, the system can edit multiple sets of welding temperature curves. Each set of temperature curves can be set with different temperature ranges, and different temperature curves can be used in the same program to weld different welding points.

2. In response to the differences in energy requirements for product solder joints, the system can edit multiple sets of welding temperature curves. Each set of temperature curves can be set with different temperature ranges, and different temperature curves can be used in the same program to weld different welding points.

Solder-Ring Welding

1. Suitable for 3C electronics, home appliances, and automotive electronics industry, especially for soldering of PCBA\FPCA plug-ins.

2. Non-contact tin melting, small thermal impact.

3. Tin ring loading synchronized with welding, accurate and efficient.

2. Non-contact tin melting, small thermal impact.

3. Tin ring loading synchronized with welding, accurate and efficient.

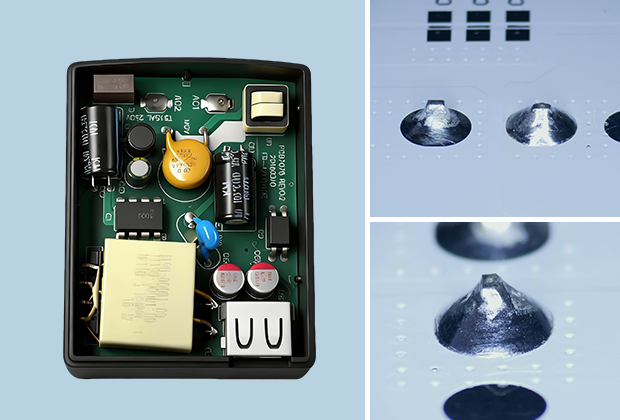

Dispensing

1. Non-contact jet dispensing technology, with a frequency of up to hundreds of times per second, is significantly faster than traditional manual or contact dispensing, greatly improving production efficiency.

2. It is suitable for precision dispensing in industries such as mobile digital products, wearable electronic devices, SMT, LED, and automotive electronics.

3. Automated equipment can operate continuously without interruption, making it particularly suitable for large-scale mass production.

2. It is suitable for precision dispensing in industries such as mobile digital products, wearable electronic devices, SMT, LED, and automotive electronics.

3. Automated equipment can operate continuously without interruption, making it particularly suitable for large-scale mass production.

Recommend: