Brittle Material Industry

Driven by the increasingly vigorous demand of brittle material industry, new manufacturing processes have emerged. Advantage of laser processing brittle materials is laser welding - direct laser welding without any additives; It can realize sealing welding in a wide range, without edge collapse and microcrack, and the welding area can not be seen by visual inspection, which overcomes the process difficulties of optical grade gap requirements.

Because of its fragile features, it is very difficult to process micro holes by ordinary laser process. When ultra fast laser is used for micro hole processing, there is no physical contact and no mechanical stress acting on the film, which reduces the occurrence of fragmentation. The ultra fast laser spot is small and the processing precision is high, which can realize the corner radian of < 10um.

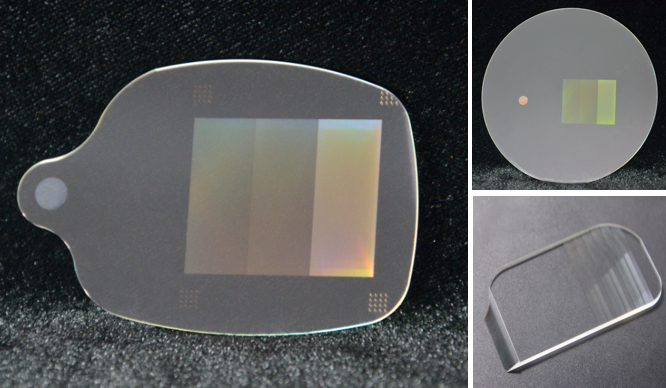

AR Lens Cutting And Cracking

1.Ultra-Precision Cutting:Specifically designed for ultra-thin AR lenses (0.2-1mm) and optical coated glass, with cutting accuracy up to ±0.02mm, ensuring chip-free edges and no light transmission loss.

2.Non-Contact Laser Cutting:Laser-based cutting technology eliminates physical contact, preventing material stress damage and maintaining coating integrity.

3.High-Stability Motion System: Equipped with a marble linear motor stage for nanometer-level motion stability, ensuring consistent cutting performance.

2.Non-Contact Laser Cutting:Laser-based cutting technology eliminates physical contact, preventing material stress damage and maintaining coating integrity.

3.High-Stability Motion System: Equipped with a marble linear motor stage for nanometer-level motion stability, ensuring consistent cutting performance.

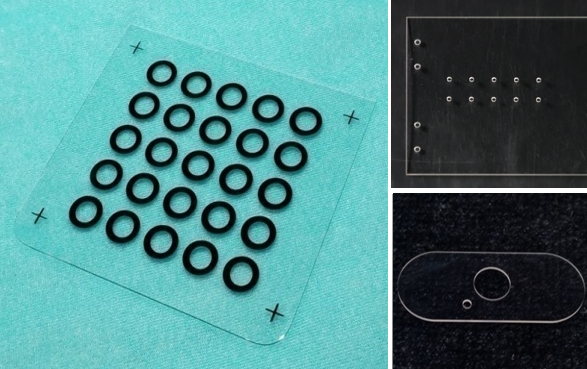

TGV Glass Drilling

1.Precision Non-Contact Processing: Laser-based drilling minimizes material damage with micron-level accuracy, ensuring clean through-holes in glass substrates.

2. User-Friendly & Low-Maintenance Design: Intuitive interactive interface simplifies operation, while modular components reduce maintenance downtime.

3. High-Stability & Smart Control: Marble linear stage with self-calibration guarantees nanometer-level positioning, paired with independently developed control system for consistent quality.

2. User-Friendly & Low-Maintenance Design: Intuitive interactive interface simplifies operation, while modular components reduce maintenance downtime.

3. High-Stability & Smart Control: Marble linear stage with self-calibration guarantees nanometer-level positioning, paired with independently developed control system for consistent quality.

UTG Ultra-thin Glass Cutting

1. Ultra-Thin Processing: Thickness range: 0.03-0.1mm, optimized for flexible display cover glass.

2. Minimal Chipping: Chipping < 0.01mm for clean edge quality.

3. High-Speed Contact-Free Cutting:

Non-contact laser cutting with minimal thermal impact, 60-95 seconds per piece (8-10").

2. Minimal Chipping: Chipping < 0.01mm for clean edge quality.

3. High-Speed Contact-Free Cutting:

Non-contact laser cutting with minimal thermal impact, 60-95 seconds per piece (8-10").

Sapphire Cutting

1. Ultra-Thin Sapphire Processing: Supports cutting of 0.2-0.6mm thick sapphire, ideal for home/side button covers and camera protection lenses.

2. Micron-Level Chipping Control: Chipping < 0.01mm for clean edges, enhancing product yield.

3. High-Speed Contact-Free Cutting: Short laser pulse duration minimizes thermal impact, with linear motor enabling 2 seconds per piece (φ11.76mm, T0.3mm).

2. Micron-Level Chipping Control: Chipping < 0.01mm for clean edges, enhancing product yield.

3. High-Speed Contact-Free Cutting: Short laser pulse duration minimizes thermal impact, with linear motor enabling 2 seconds per piece (φ11.76mm, T0.3mm).