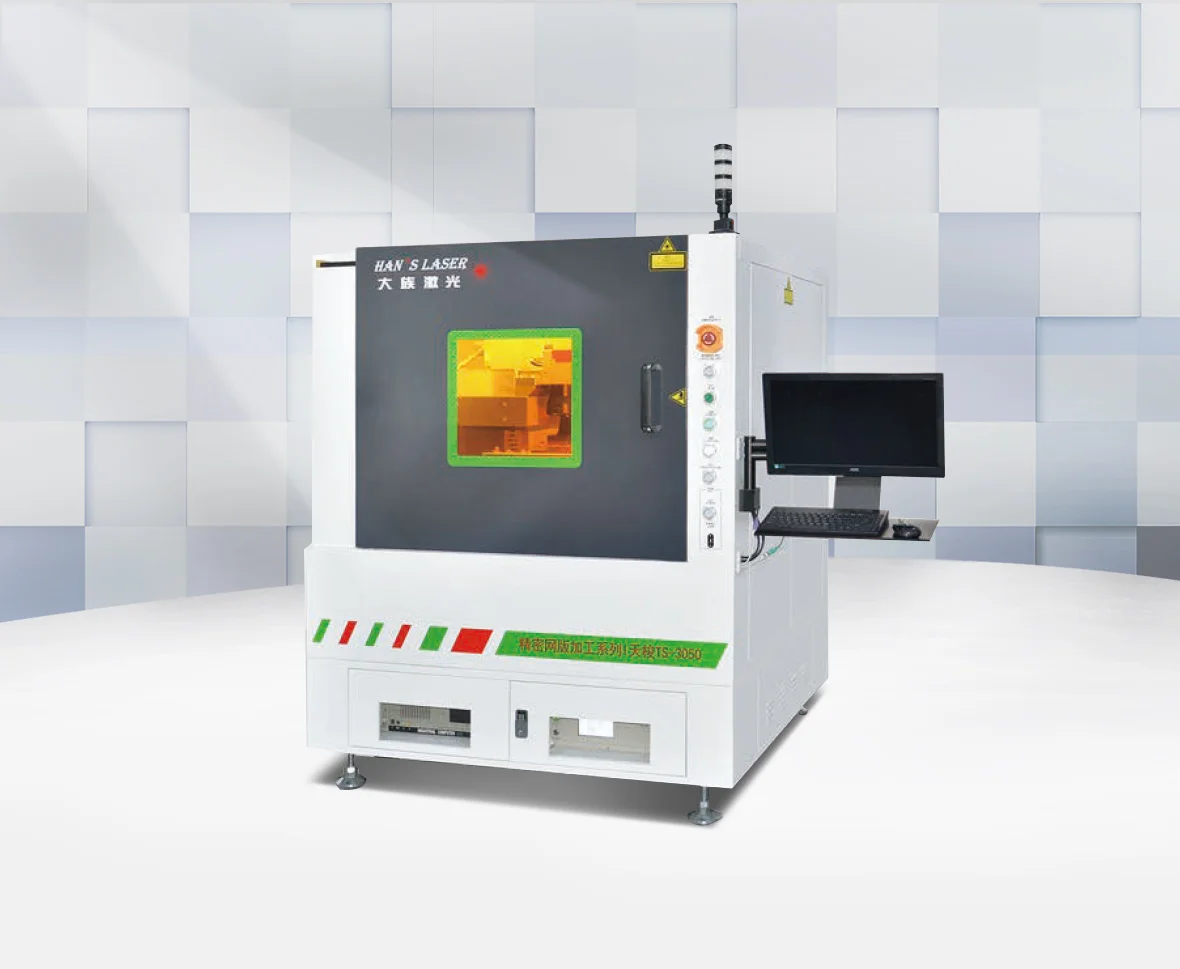

Laser screen plate cutting machine for PI film/Steel Mesh.

Brief Description

Mainly used for laser pattern processing of solar screen printing PI film material screen or stencil removal for meshless screen production

Categories

PV Industry

Contact Us

Main Features

Good processing quality: no burning, no glue residue, good line width consistency in film cutting; no residue in steel mesh cutting, less dust adhesion;

High flexibility: Compatible with conventional screen and non-knotted screen, you can choose a variety of cutting methods;

High precision: high-precision CCD positioning system + high-precision XY platform (repeated positioning accuracy ±1um).

Good processing quality: no burning, no glue residue, good line width consistency in film cutting; no residue in steel mesh cutting, less dust adhesion;

High flexibility: Compatible with conventional screen and non-knotted screen, you can choose a variety of cutting methods;

High precision: high-precision CCD positioning system + high-precision XY platform (repeated positioning accuracy ±1um).

Main Parameters

| Project | Solar screen film cutting machine | Solar Mesh Stencil Cutting Machine |

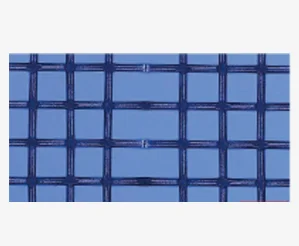

| Processing object | Screen PI film | Knot-free mesh |

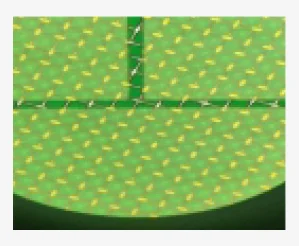

| Technical indicators | The taper of fine grid/anti-break grid/gradient grid can be adjusted from 6-8um; The total taper of both sides of busbar cutting is less than or equal to 10um; Fine grid incision width tolerance ±1um; Overall graphic cutting size error ±5um |

Warp cutting number: 2 or 3 optional With the function of software to automatically correct the number of cutting strips |

| Processing quality | No burning, no wire damage, no glue residue | No residue, no obvious burrs |

| efficiency | About 30min (according to the complexity of the graphics and size differences, time will vary) |

About 30min (according to product size differences, time will vary) |

Sample