Press release

12

2025,09

Application of UV and ultrafast lasers

Today we will discuss in detail the practical applications of ultraviolet (UV) lasers and ultrafast lasers. Although these two types of lasers is kind of overlapped (ultrafast lasers can be in the ultraviolet band), their unique characteristics (short wavelength vs. ultra short pulse) determine their respective application fields.

More

04

2025,09

Spotlight on Han's Laser: Advanced Laser machines as National Pillar & Smart Manufacturing Driver

Han's Laser Advanced Laser Display

More

29

2025,08

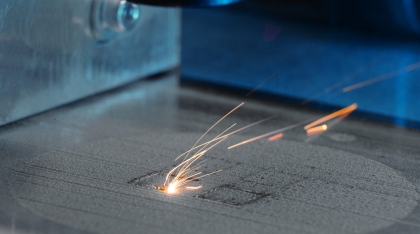

Laser 3D Printing: Reshaping 3C Digital Field

In the fast-evolving landscape of the consumer electronics (3C) industry, "sleekness, high performance, personalization" are the core competitive pillars.

More

22

2025,08

Han's Laser made 2025 Top 50 Tech Companies list of Fortune China.

Han's Laser made a strong appearance on the list of "China's Top 50 Tech Companies 2025relying on its continuous innovation and outstanding contributions in high-end laser equipment.

More

21

2025,08

2025 Formnext Asia Shenzhen

2025 Formnext Asia Shenzhen will grandly open at the Shenzhen World Exhibition and Convention Center from August 26th to 28th!

More

14

2025,08

The Principle of Laser 3D Printing Technology

Laser 3D printing, also known as additive manufacturing, is a technology that builds three - dimensional objects by layer - by - layer accumulation of materials.

More