2025 Formnext Asia Shenzhen

2025 Formnext Asia Shenzhen will grandly open at the Shenzhen World Exhibition and Convention Center from August 26th to 28th! As a dedicated manufacturer and innovative strength in additive manufacturing, Han's Matrix3D will showcase a variety of core equipment at the exhibition with full preparation to meet the expectations of the industry. We sincerely invite industry partners from all around the world to visit the site and join this industry feast that integrates technical exchange, trend discussion and business opportunity connection!

Product Features:

1. Safe, stable, and efficient

2. Powder feeding, bidirectional high-efficiency variable-speed powder spreading

3. Small spot size, suitable for printing high-precision parts

4. Equipped with intelligent powder spreading and real-time process monitoring module

5. Green laser, suitable for high-reflectivity, refractory metals such as copper, aluminum, and tungsten

Application areas:

Suitable for industries such as heat sinks, 3C, new energy vehicles, and aerospace.

Material applicability:

The M360G green laser printing equipment demonstrates excellent adaptability to high-reflectivity metals such as copper, gold, and aluminum, making the printing process more convenient and efficient for these materials. It also provides an outstanding solution for processing high-reflectivity materials. Additionally, green laser energy can more effectively interact with refractory metals such as tungsten, tantalum, molybdenum, zirconium, niobium, and chromium, resulting in superior forming effects;

Product Features:

1. Optional dual galvanometers;

2. Four-laser system for efficient printing;

3. Optional intelligent monitoring and graft printing function modules;

4. Fully open process parameter package for easy secondary development;

Product Applications:

Suitable for industries such as prototyping, shoe molds, 3C, and automotive.

Mold Industry:

The application of 3D printing in the mold industry reduces the production cycle of molds and lowers manufacturing costs.

Automotive Industry:

Optimized structural design can significantly reduce vehicle weight and fuel consumption; R&D prototyping eliminates the need for mold making, shortening the vehicle development cycle; mass production enables digital manufacturing without the need for tooling fixtures.

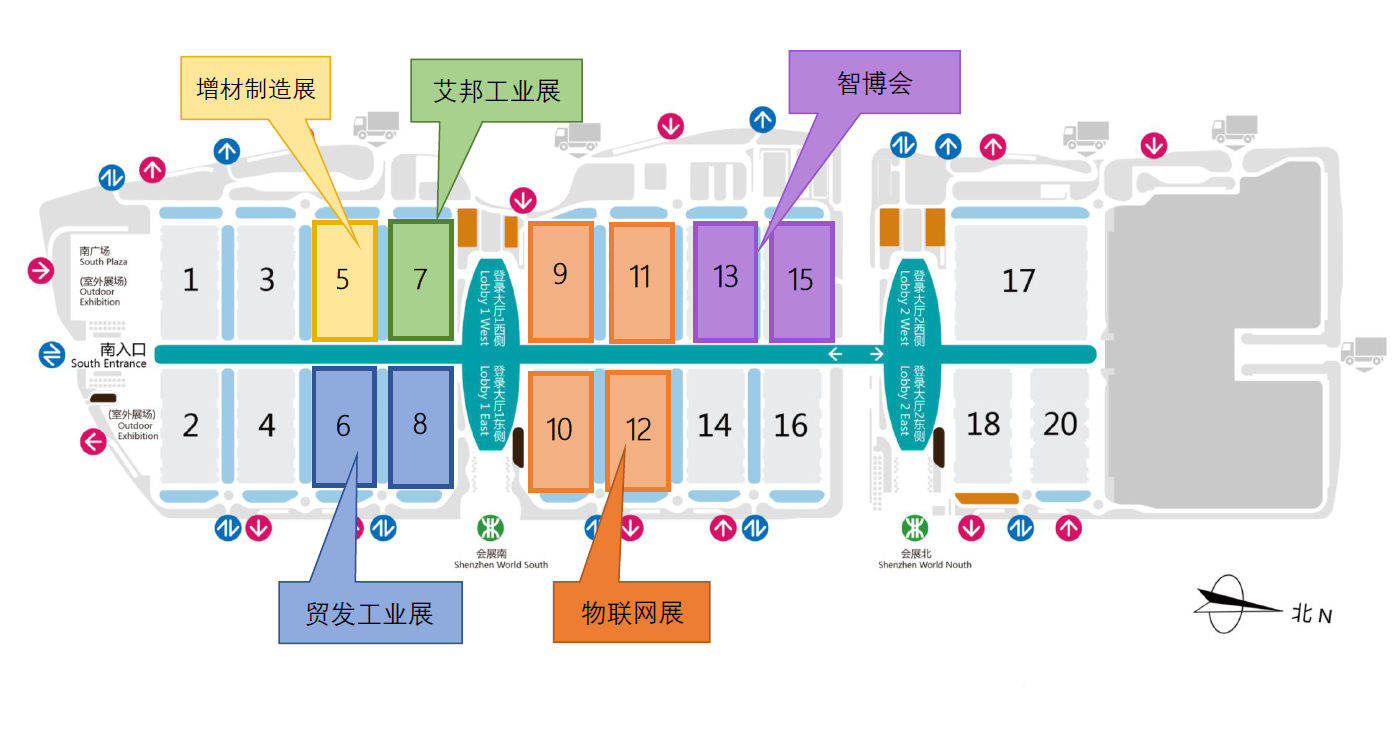

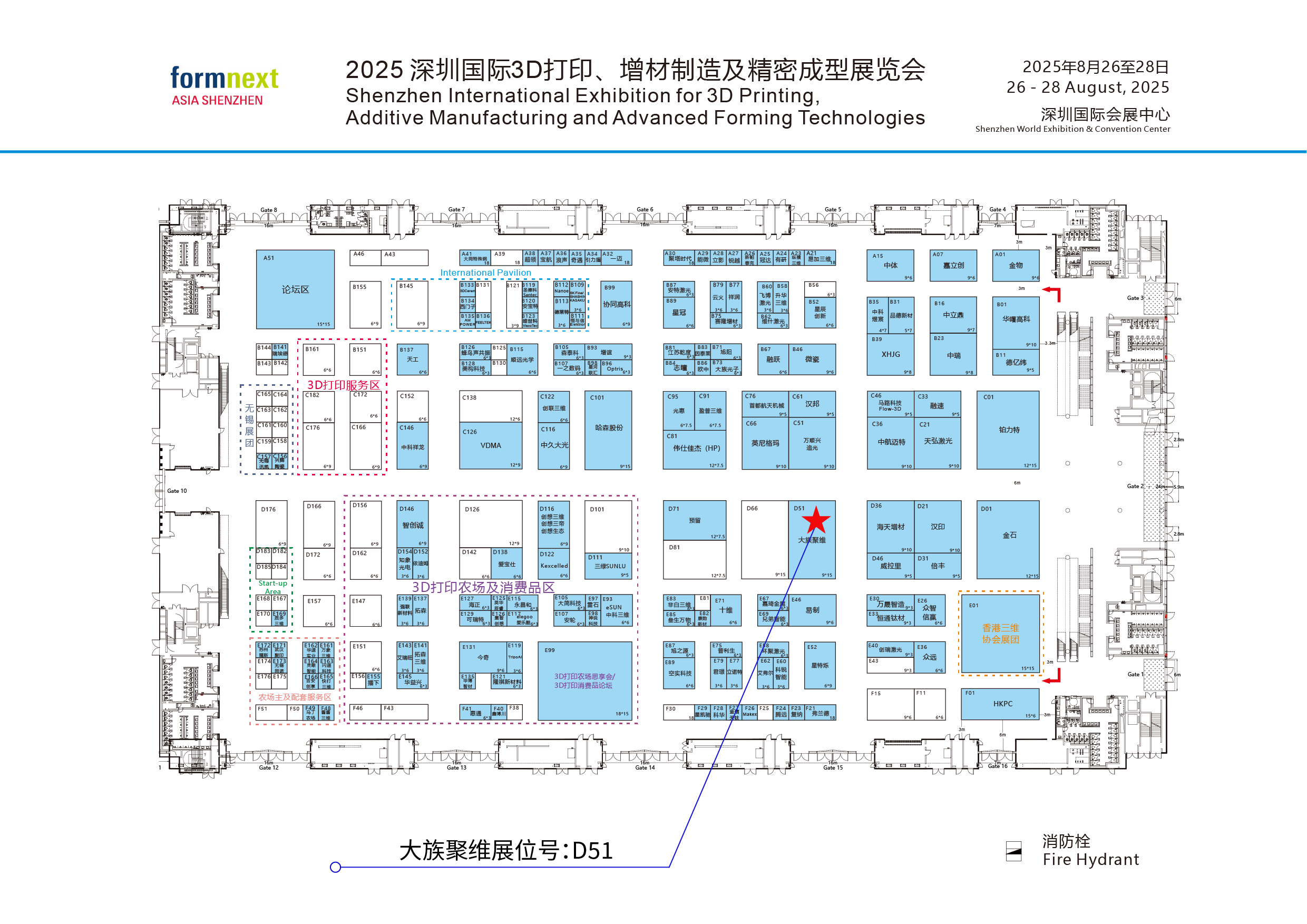

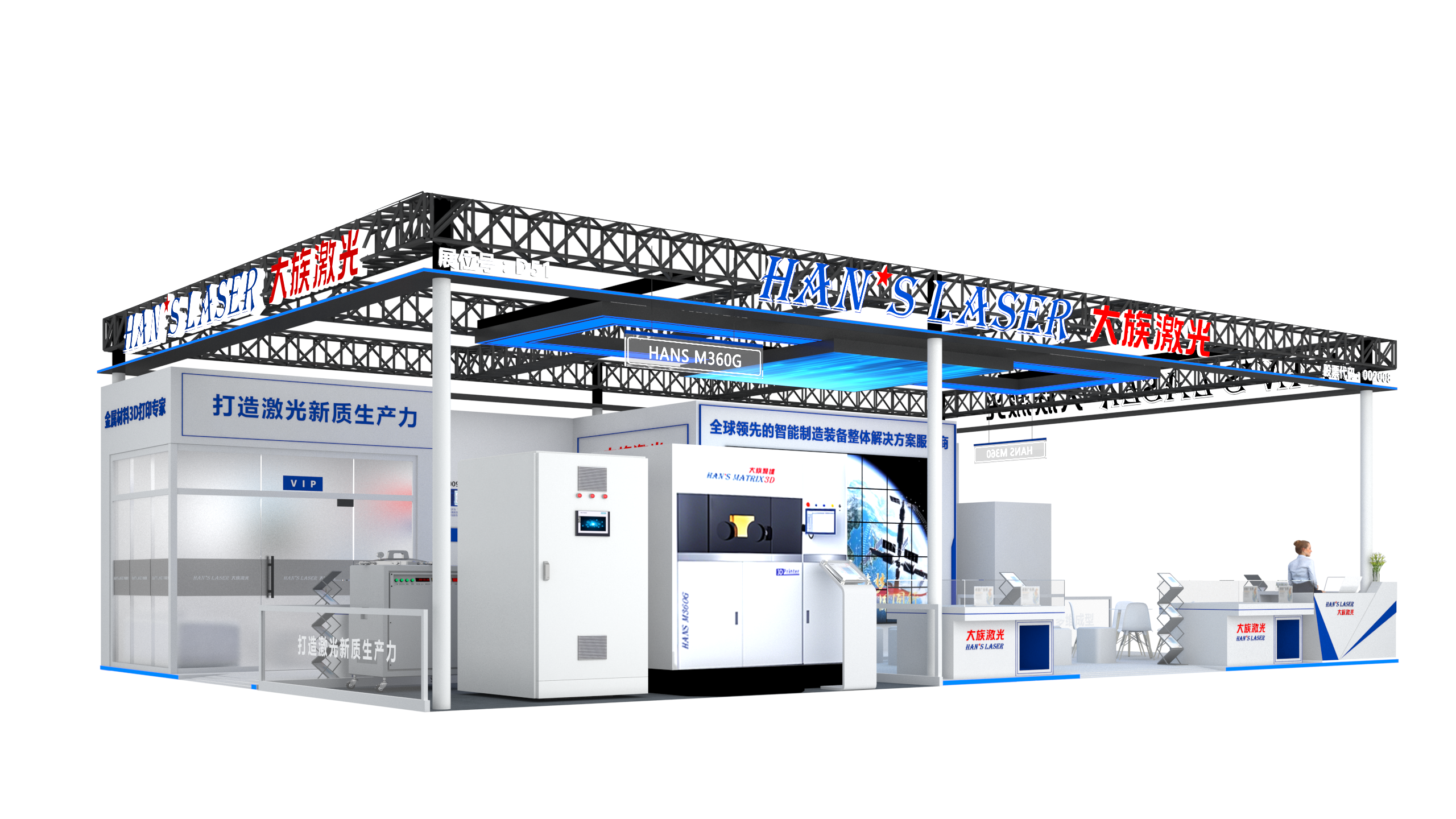

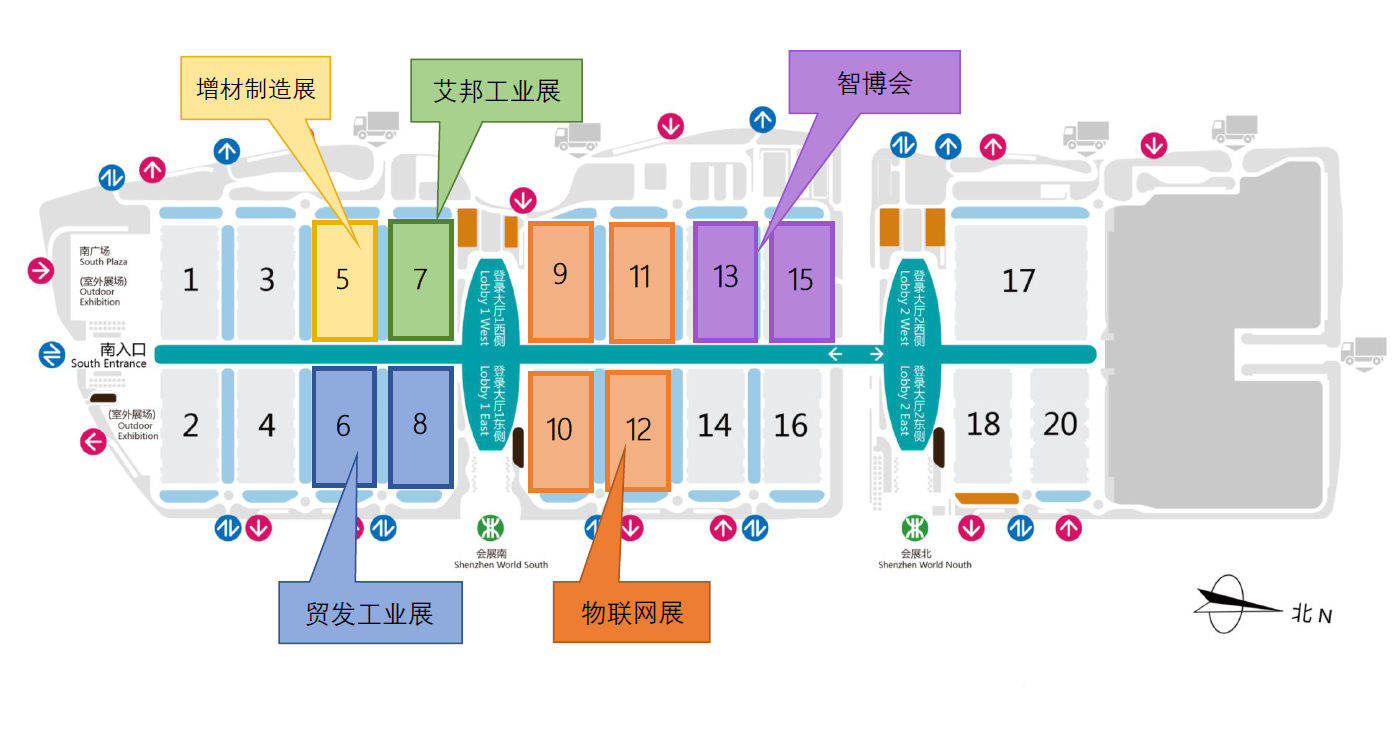

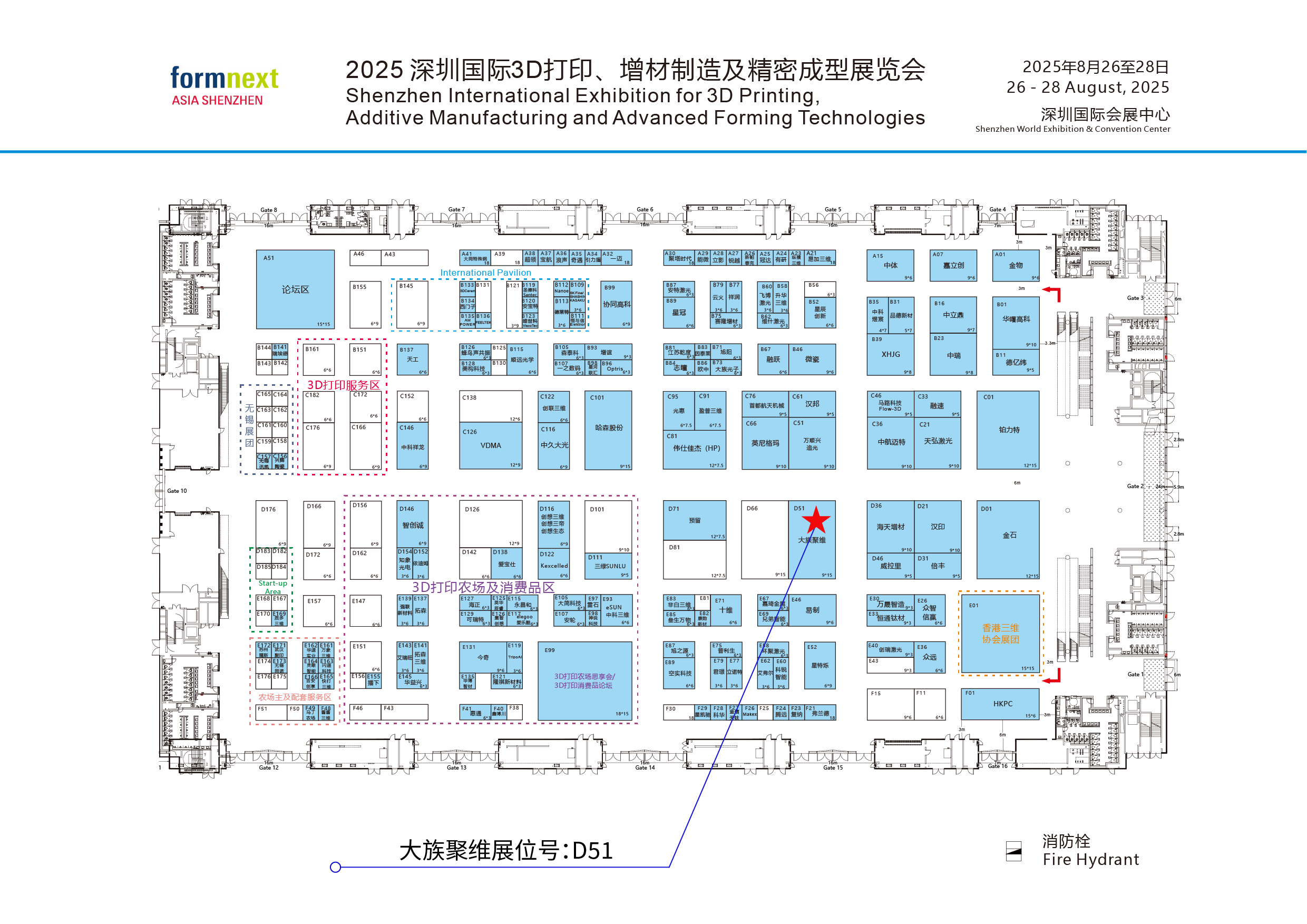

Exhibition Guide

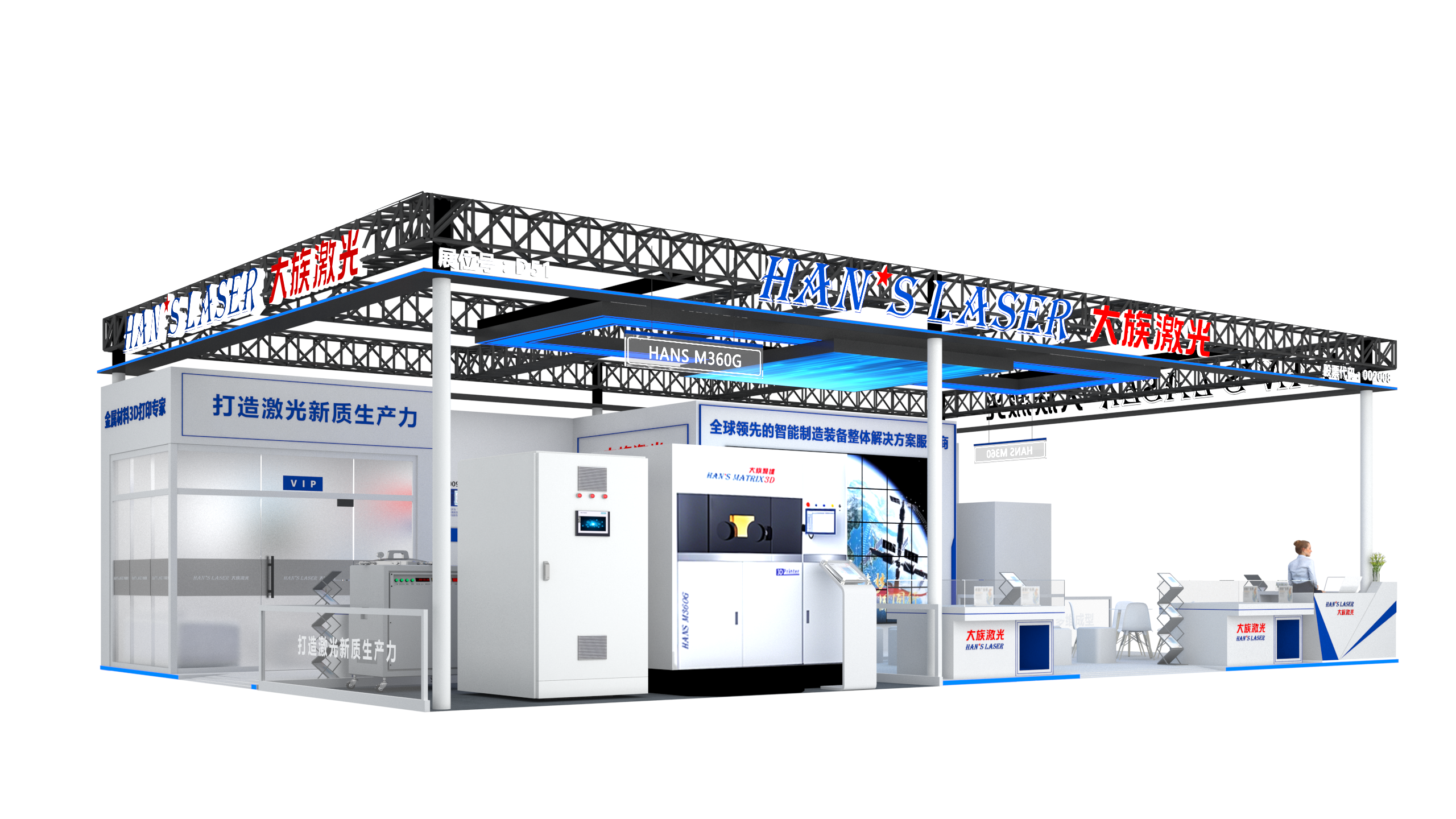

Booth Overview

Exhibition Equipment-HANS M360G

Product Features:

1. Safe, stable, and efficient

2. Powder feeding, bidirectional high-efficiency variable-speed powder spreading

3. Small spot size, suitable for printing high-precision parts

4. Equipped with intelligent powder spreading and real-time process monitoring module

5. Green laser, suitable for high-reflectivity, refractory metals such as copper, aluminum, and tungsten

Application areas:

Suitable for industries such as heat sinks, 3C, new energy vehicles, and aerospace.

Material applicability:

The M360G green laser printing equipment demonstrates excellent adaptability to high-reflectivity metals such as copper, gold, and aluminum, making the printing process more convenient and efficient for these materials. It also provides an outstanding solution for processing high-reflectivity materials. Additionally, green laser energy can more effectively interact with refractory metals such as tungsten, tantalum, molybdenum, zirconium, niobium, and chromium, resulting in superior forming effects;

Exhibition Equipment-HANS M360

Product Features:

1. Optional dual galvanometers;

2. Four-laser system for efficient printing;

3. Optional intelligent monitoring and graft printing function modules;

4. Fully open process parameter package for easy secondary development;

Product Applications:

Suitable for industries such as prototyping, shoe molds, 3C, and automotive.

Mold Industry:

The application of 3D printing in the mold industry reduces the production cycle of molds and lowers manufacturing costs.

Automotive Industry:

Optimized structural design can significantly reduce vehicle weight and fuel consumption; R&D prototyping eliminates the need for mold making, shortening the vehicle development cycle; mass production enables digital manufacturing without the need for tooling fixtures.

Exhibition Benefits Preview

1. Interactive Raffle: The exhibition has prepared multiple gifts. Welcome to participate in the interactive activities on-site and take the gifts home!

2. Technical Sharing: Senior R&D engineers from Han’s Matrix3D will share their expertise, exploring the possibilities of green light equipment.

3. Gift for following: On-site visitors who scan and follow the Han’s Matrix WeChat Channel account/Tik Tok account/Rednote account will receive a custom canvas bag.

4. Online Live Stream: Cooperating with media platforms, we will launch the "Formnext Virtual Exhibition Tour". Please stay tuned!

2. Technical Sharing: Senior R&D engineers from Han’s Matrix3D will share their expertise, exploring the possibilities of green light equipment.

3. Gift for following: On-site visitors who scan and follow the Han’s Matrix WeChat Channel account/Tik Tok account/Rednote account will receive a custom canvas bag.

4. Online Live Stream: Cooperating with media platforms, we will launch the "Formnext Virtual Exhibition Tour". Please stay tuned!