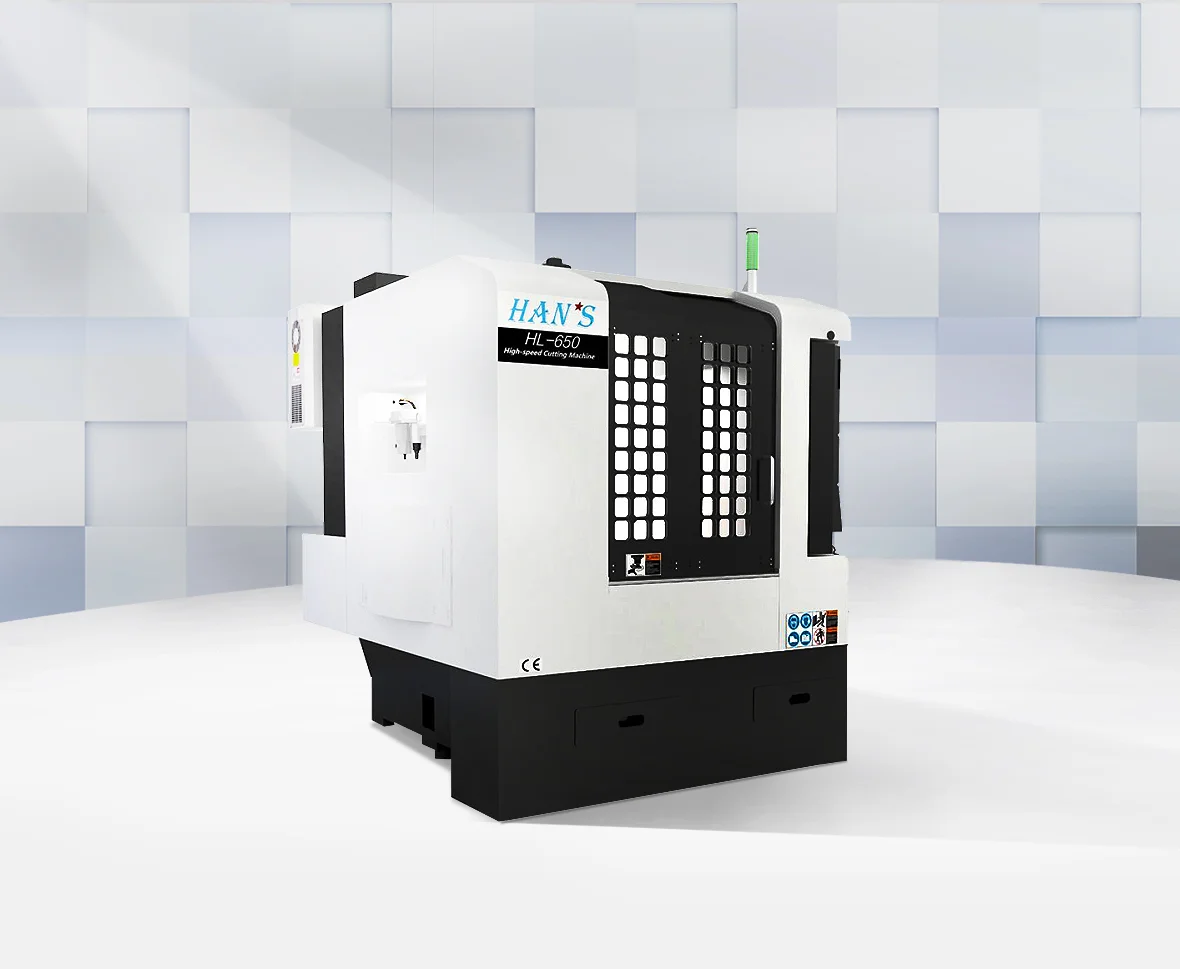

HL650

Brief Description

Mobile phone panel processing / Precision keypad, fixture batch processing / Electrode, jewelry glasses, clocks, small metal parts processing / PC, acrylic processing / Glass, sapphire, ceramic processing

Categories

Precision engraving and milling machine

Contact Us

Features:

1. The castings are analyzed by the finite element analysis method. The integration of the molding technology, the box mechanism and the ribs are used to improve the rigidity of the machine.

2. The spindle adopts HSK E32 high-speed electric spindle, which has stable performance, small dynamic balance and good high light effect.

3. The three-axis screw rod adopts two-stage pre-tensioning design, which is more rigid than single-end pre-tensioning, has little influence on thermal variables, and has high precision and stability.

4. The three-axis adopts the rail support to support heavy load and move quickly to ensure accurate positioning.

5. It adopts high-precision imported grinding grade ball screw and pre-tightening nut, which has high transmission precision and ensures small mechanical error for a long time.

6. The rib reinforcement structure in the spindle cavity provides stable support of the spindle to ensure the working accuracy at high speed.

7. The moving parts are fully sealed.

8. Air source filtration: All Japanese SMC parts are used.

9. Lubrication system: regular automatic oil supply system, long-term maintenance-free, grease lubrication and drip prevention.

10. Equipped with automatic tool change system to improve processing efficiency.

2. The spindle adopts HSK E32 high-speed electric spindle, which has stable performance, small dynamic balance and good high light effect.

3. The three-axis screw rod adopts two-stage pre-tensioning design, which is more rigid than single-end pre-tensioning, has little influence on thermal variables, and has high precision and stability.

4. The three-axis adopts the rail support to support heavy load and move quickly to ensure accurate positioning.

5. It adopts high-precision imported grinding grade ball screw and pre-tightening nut, which has high transmission precision and ensures small mechanical error for a long time.

6. The rib reinforcement structure in the spindle cavity provides stable support of the spindle to ensure the working accuracy at high speed.

7. The moving parts are fully sealed.

8. Air source filtration: All Japanese SMC parts are used.

9. Lubrication system: regular automatic oil supply system, long-term maintenance-free, grease lubrication and drip prevention.

10. Equipped with automatic tool change system to improve processing efficiency.

Specifications:

| No. | Item | Unit | HL-650 | |

| 1 | Working area | X/Y/Z axis stroke | mm | 520/600/280 |

| 2 | Minimum distance from the spindle nose to the worktable | mm | 120~400 | |

| 3 | Work table | Table size | mm | 520*620 |

| 4 | Max. load | Kg | 500 | |

| 5 | T-slot size | mm | 6-14*100 | |

| 6 | Main drive | Max rotation speed | rpm | 36000 |

| 7 | Max torque(S6 40% DC) | Nm | 5.8 | |

| 8 | Rated torque(S1 100% DC) | Nm | 2.7 | |

| 9 | Max power(S6 40% DC) | Kw | 9 | |

| 10 | Rated power(S1 100% DC) | Kw | 6 | |

| 11 | Tool charger | Tool type | HSK-32 | |

| 12 | Tool magazine | Pockets | 12 | |

| 13 | Tool magazine form | Semi-circular umbrella knife | ||

| 14 | Max tool diameter (full tools/adjacent tools) | mm | 80 | |

| 15 | Max tool length | mm | 150 | |

| 16 | Max tool weight | Kg | 2 | |

| 17 | Tool-tool change time(T to T) | sec | 1.5 | |

| 18 | Chip-chip change time(C to C) | sec | 3.8 | |

| 19 | Feed | Feed velocity(X/Y/Z) | m/min | X 10/ Y 10/Z10 |

| 20 | Rapid moving speed(X/Y/Z) | m/min | 15/15/15 | |

| 21 | Acceleration(X/Y/Z) | m/s2 | X 10/ Y 10/Z10 | |

| 22 | Linear guide size(X/Y/Z) | mm | 30/30/30 | |

| 23 | Ball screw size(X/Y/Z) | ∮* incline | 32/32/40 | |

| 24 | Position accuracy(X/Y/Z) | mm | 0.005/300 | |

| 25 | Repeated accuracy(X/Y/Z) | mm | ±0.003 | |

| 26 | Mechnical data | Mechnical size(with water tank) | mm | 2040*1270*2220 |

| 27 | Mechnical weight(without water tank) | Kg | 4600 | |

| 28 | Control system | Siemens Sinumerik 828D | Siemens 828D | |

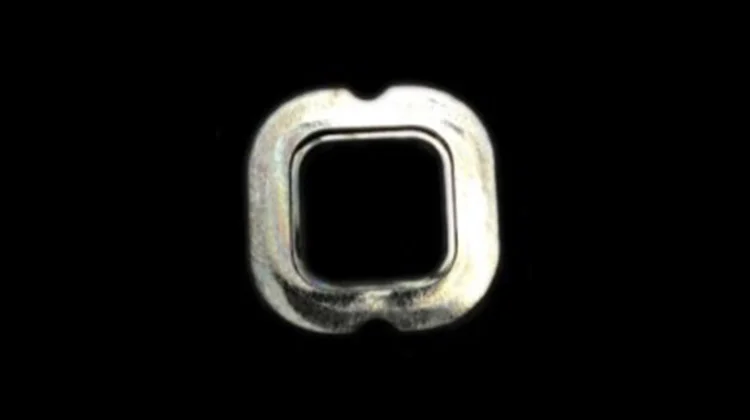

Sample