The similarities and differences between laser 3D printing and laser welding

Laser 3D printing (usually referring to laser selective melting SLM) and laser welding are advanced manufacturing technologies that utilize high-energy density laser beams to interact with materials. They share profound similarities in principle, but have fundamental differences in goals, processes, and applications.

Core similarity

1)The physical principles are the same:

Both are based on the physical principles of laser material interaction. After being absorbed by the material, high-energy laser beams are converted into thermal energy, causing rapid heating, melting, and even vaporization of local areas of the material.

2) They all involve melt pool dynamics, where the metal melts to form a melt pool, which flows under surface tension, Marangoni effect, gravity, and other forces, and then rapidly cools and solidifies.

Deep Understanding of Differences: A Vivid Metaphor

You can imagine them as' writing with a laser pen ':

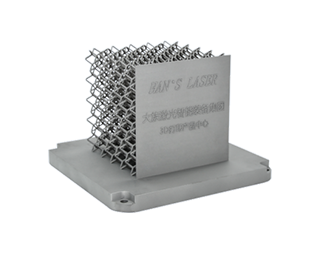

Laser 3D printing is like using a pen filled with iron powder to "draw" a three-dimensional, solid metal letter layer by layer on a platform. You not only drew the outline, but also filled the entire interior. This is a process of creation from scratch, belonging to additive manufacturing.

Laser welding is like holding a high-energy laser pointer as a 'glue', tracing along the seam of two already made metal parts to fuse them together. This is a process of "connection" and merging into one.

In summary, laser 3D printing and laser welding are brother technologies of the same origin but different directions. They share the same laser physics core, but are developing towards completely different application directions:

The core of laser 3D printing is "manufacturing", pursuing design freedom and maximizing material utilization, committed to creating unprecedentedly complex structures.

The core of laser welding is "connection", pursuing connection strength, speed, and sealing, committed to efficiently and reliably combining existing components into larger units.

Core similarity

1)The physical principles are the same:

Both are based on the physical principles of laser material interaction. After being absorbed by the material, high-energy laser beams are converted into thermal energy, causing rapid heating, melting, and even vaporization of local areas of the material.

2) They all involve melt pool dynamics, where the metal melts to form a melt pool, which flows under surface tension, Marangoni effect, gravity, and other forces, and then rapidly cools and solidifies.

Deep Understanding of Differences: A Vivid Metaphor

You can imagine them as' writing with a laser pen ':

Laser 3D printing is like using a pen filled with iron powder to "draw" a three-dimensional, solid metal letter layer by layer on a platform. You not only drew the outline, but also filled the entire interior. This is a process of creation from scratch, belonging to additive manufacturing.

Laser welding is like holding a high-energy laser pointer as a 'glue', tracing along the seam of two already made metal parts to fuse them together. This is a process of "connection" and merging into one.

In summary, laser 3D printing and laser welding are brother technologies of the same origin but different directions. They share the same laser physics core, but are developing towards completely different application directions:

The core of laser 3D printing is "manufacturing", pursuing design freedom and maximizing material utilization, committed to creating unprecedentedly complex structures.

The core of laser welding is "connection", pursuing connection strength, speed, and sealing, committed to efficiently and reliably combining existing components into larger units.