Application of Laser Technology in Power Battery Processing

Due to the increasing complexity of battery production, the number of scratches generated during the production process has increased. These scratches have caused the area around the tank mouth to become dirty, reducing the welding quality of the top cover. Initially, one company SDI used cotton with cleaner to clean these scratches, but the low efficiency forced them to seek other more efficient ways. Laser cleaning, due to its efficient and environmentally friendly advantages, was used by the company SDI to clean all scratches around the shell and remove other unnecessary materials.

It is reported that the company SDI is continuing to develop its fifth generation battery production process. So far, Z-type stacking and label welding have been applied in production, and laser technology is also planned to be applied to the cutting process of battery cells to improve the yield rate of batteries.

In the manufacturing of power batteries

What are the specific applications of laser processing technology?

1. Laser cutting

Before the emergence of laser technology, traditional machinery was usually used to process and cut the pole ears of power lithium batteries in the production process of power batteries. Traditional die cutting equipment generated cutting burrs and a large heat affected zone during use, which could affect the performance of subsequent lithium batteries and potentially cause various dangerous problems such as battery overheating, short circuits, and even explosions.

Laser cutting has advantages such as no consumables, flexible cutting shape, edge quality control, higher accuracy, and lower operating costs. The cutting effect is better than traditional die cutting, with small burrs and a small heat affected zone, greatly reducing the safety hazards of lithium batteries. At the same time, it is conducive to reducing manufacturing costs, improving production efficiency, and significantly shortening the new product die cutting cycle.

Laser cutting can mainly be applied to metal foil cutting, metal foil cutting (pole ear cutting), and isolation film cutting in battery production.

2. Laser welding

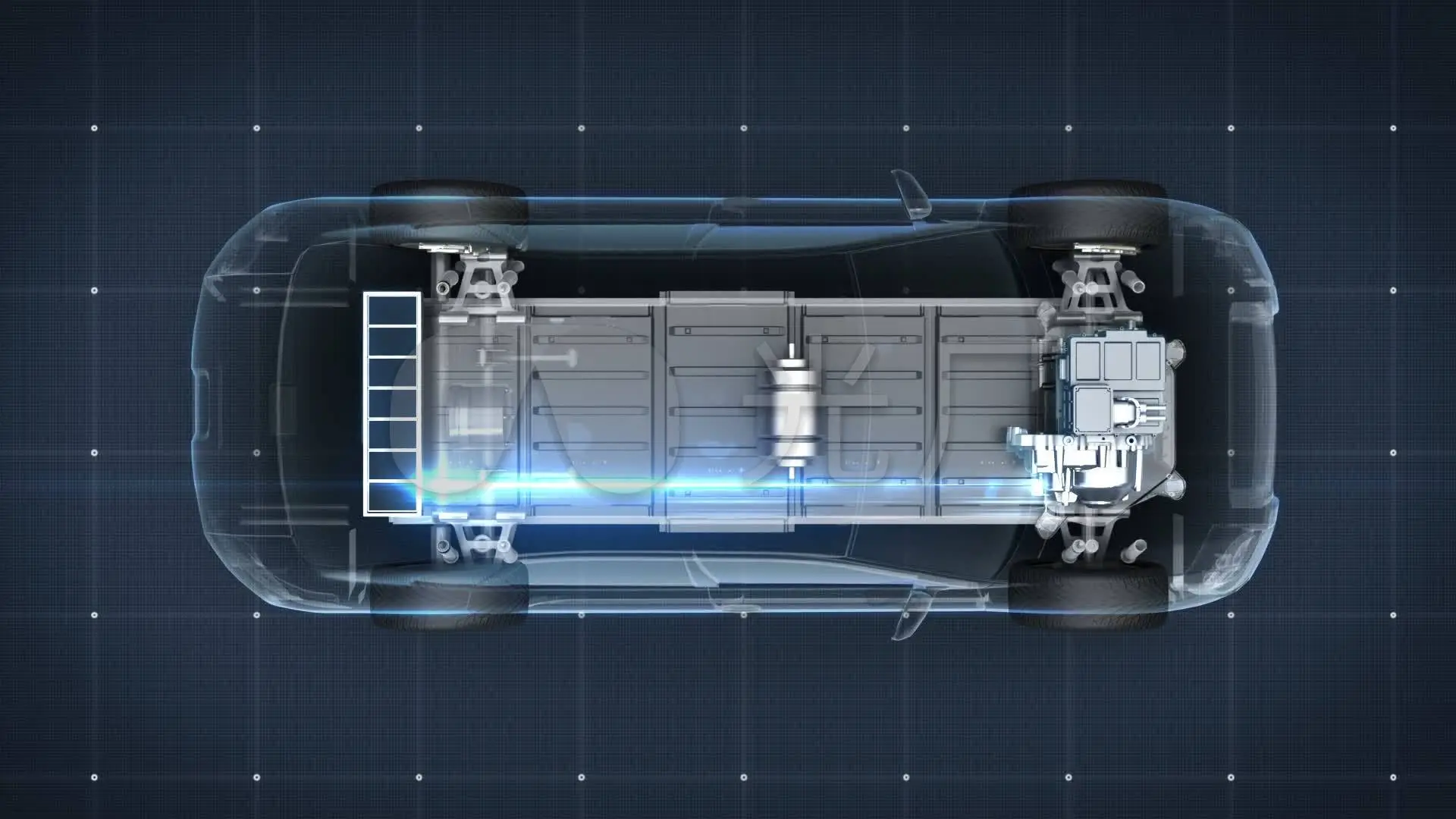

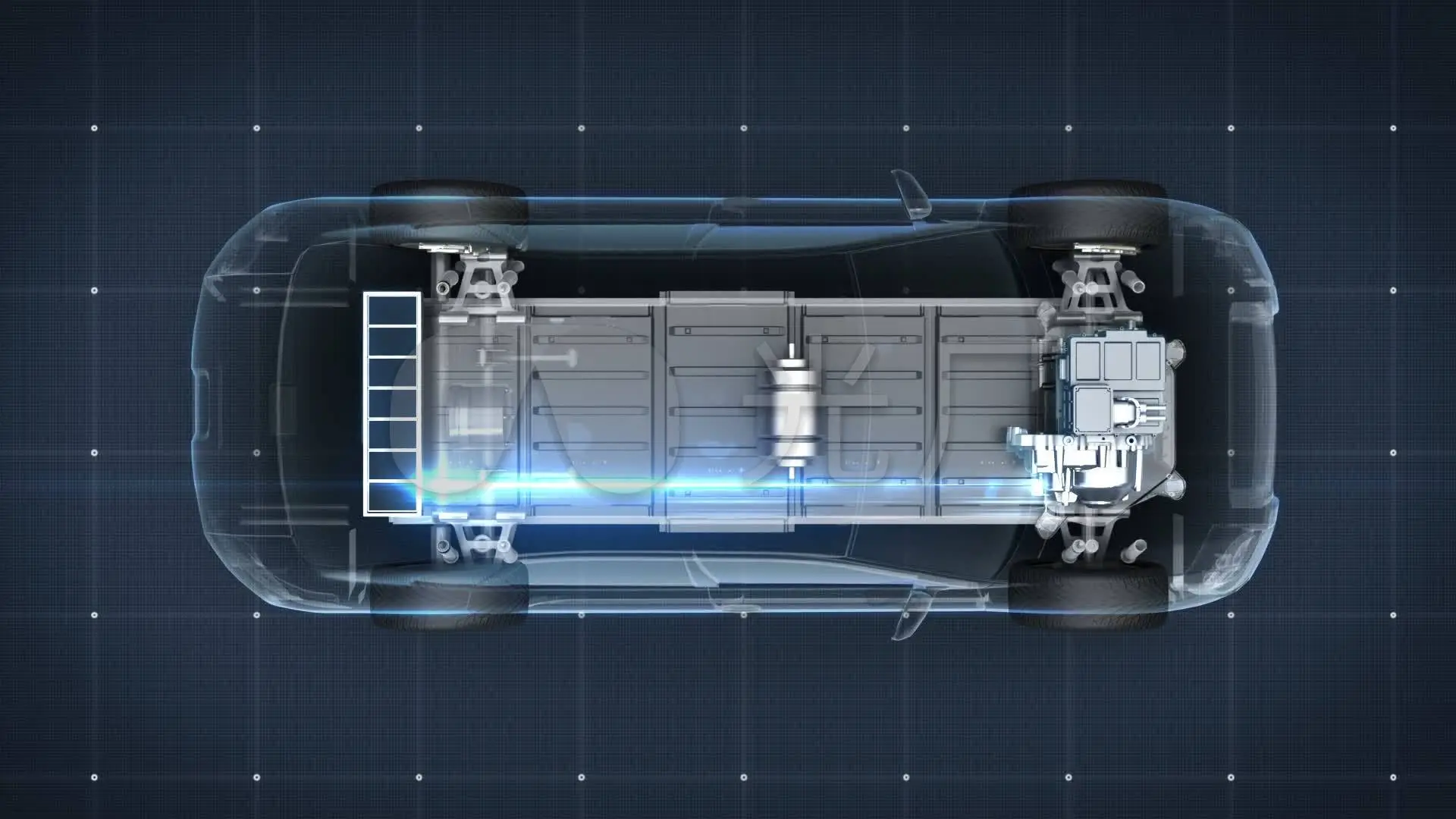

Power batteries are divided into square, cylindrical, and soft pack batteries. Currently, the popularity of square power batteries in China is relatively high. Due to the requirement of "lightweight" battery cells, the material is generally aluminum alloy, and the thickness of mainstream manufacturers' materials is about 0.8 mm. To make these thin or fine diameter wires able to withstand high-strength splicing welding or overlay welding, conventional welding processes are difficult to meet the requirements.

Laser welding has the features of energy concentration, high welding efficiency, high processing accuracy, large welding depth to width ratio, and the ability to achieve automation; Compared with argon arc welding, resistance welding, ultrasonic welding, etc., the heat input is small, the heat affected zone is small, the residual stress and deformation of the workpiece are small, the welding material loss is small, non-contact processing is possible, the efficiency is higher, the welding accuracy is higher, and the safety is also higher. It has been widely used in the welding of components such as pole ears, battery cells, sealing nails, soft connections, explosion-proof valves, battery modules, etc.

3. Laser cleaning

In addition to the cleaning of the battery top cover by a company SDI before welding, laser cleaning technology can also be used in the manufacturing of lithium batteries, as well as the production of battery cells. Laser cleaning can be used before electrode coating, battery assembly process, and coating removal process. Compared with traditional mechanical scraping, foam adhesive application, or wet ethanol cleaning processes, laser has many advantages such as no damage to the substrate, precise control at the micrometer level, energy conservation and environmental protection, and can fully meet various precision cleaning requirements in battery manufacturing, greatly improving the level of battery manufacturing technology.

It is reported that the company SDI is continuing to develop its fifth generation battery production process. So far, Z-type stacking and label welding have been applied in production, and laser technology is also planned to be applied to the cutting process of battery cells to improve the yield rate of batteries.

In the manufacturing of power batteries

What are the specific applications of laser processing technology?

1. Laser cutting

Before the emergence of laser technology, traditional machinery was usually used to process and cut the pole ears of power lithium batteries in the production process of power batteries. Traditional die cutting equipment generated cutting burrs and a large heat affected zone during use, which could affect the performance of subsequent lithium batteries and potentially cause various dangerous problems such as battery overheating, short circuits, and even explosions.

Laser cutting has advantages such as no consumables, flexible cutting shape, edge quality control, higher accuracy, and lower operating costs. The cutting effect is better than traditional die cutting, with small burrs and a small heat affected zone, greatly reducing the safety hazards of lithium batteries. At the same time, it is conducive to reducing manufacturing costs, improving production efficiency, and significantly shortening the new product die cutting cycle.

Laser cutting can mainly be applied to metal foil cutting, metal foil cutting (pole ear cutting), and isolation film cutting in battery production.

2. Laser welding

Power batteries are divided into square, cylindrical, and soft pack batteries. Currently, the popularity of square power batteries in China is relatively high. Due to the requirement of "lightweight" battery cells, the material is generally aluminum alloy, and the thickness of mainstream manufacturers' materials is about 0.8 mm. To make these thin or fine diameter wires able to withstand high-strength splicing welding or overlay welding, conventional welding processes are difficult to meet the requirements.

Laser welding has the features of energy concentration, high welding efficiency, high processing accuracy, large welding depth to width ratio, and the ability to achieve automation; Compared with argon arc welding, resistance welding, ultrasonic welding, etc., the heat input is small, the heat affected zone is small, the residual stress and deformation of the workpiece are small, the welding material loss is small, non-contact processing is possible, the efficiency is higher, the welding accuracy is higher, and the safety is also higher. It has been widely used in the welding of components such as pole ears, battery cells, sealing nails, soft connections, explosion-proof valves, battery modules, etc.

3. Laser cleaning

In addition to the cleaning of the battery top cover by a company SDI before welding, laser cleaning technology can also be used in the manufacturing of lithium batteries, as well as the production of battery cells. Laser cleaning can be used before electrode coating, battery assembly process, and coating removal process. Compared with traditional mechanical scraping, foam adhesive application, or wet ethanol cleaning processes, laser has many advantages such as no damage to the substrate, precise control at the micrometer level, energy conservation and environmental protection, and can fully meet various precision cleaning requirements in battery manufacturing, greatly improving the level of battery manufacturing technology.