How much do you know about laser cleaning?

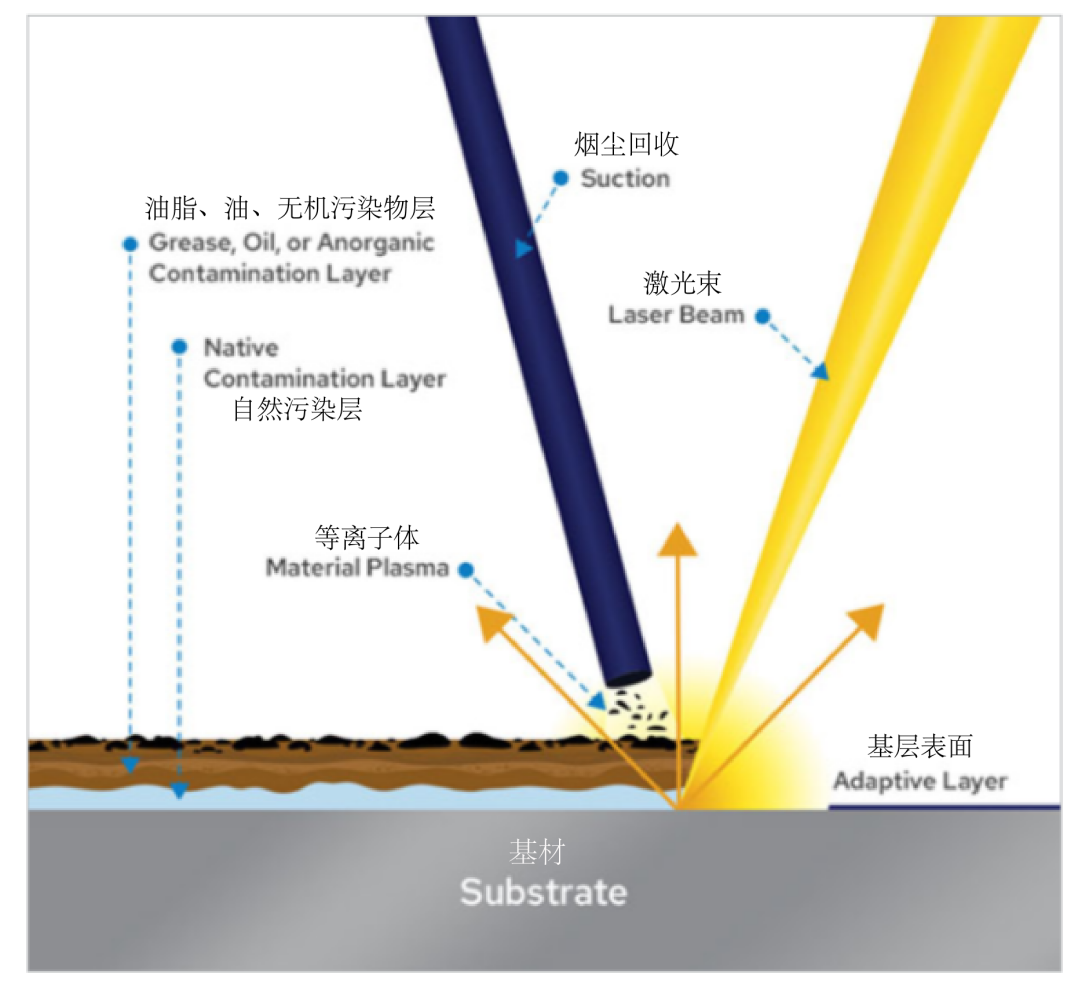

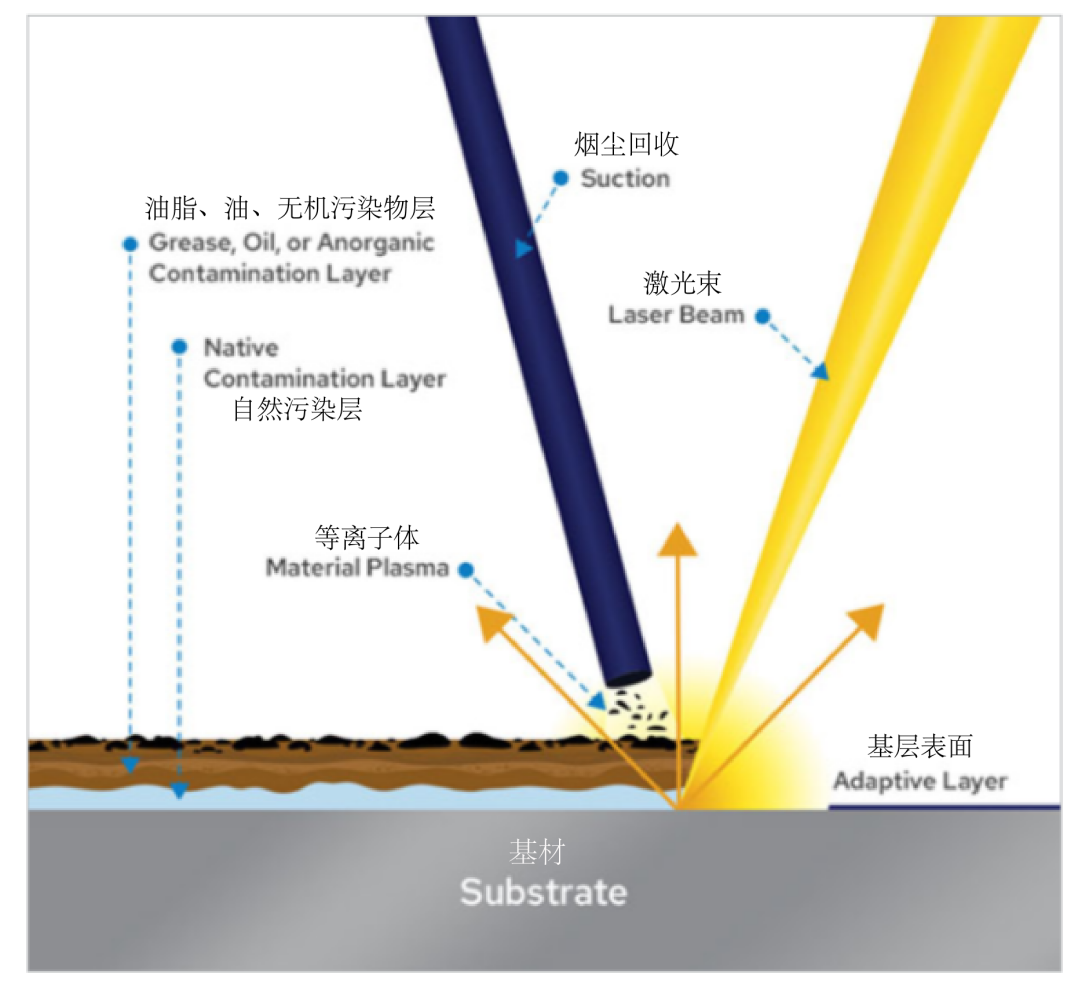

Why can laser be used for cleaning? Why does it not cause damage to the object to be cleaned? The laser uses a resonator to focus light in the same direction, and has better performance than simple wavelength and coordination. Therefore, light of all wavelengths can be used to form a laser. However, in fact, due to the limited number of media that can be excited, laser sources that can produce stable and suitable for industrial production are widely used, which are probably Nd: YAG lasers, carbon dioxide lasers and excimer lasers. Because Nd: YAG laser can be transmitted through optical fiber and is more suitable for industrial applications, it is also widely used in laser cleaning.

Compared with traditional cleaning methods such as mechanical friction cleaning, chemical corrosion cleaning, liquid solid strong impact cleaning, high-frequency ultrasonic cleaning, laser cleaning has obvious advantages.

1. Laser cleaning is a "green" cleaning method. It does not need any chemical agents and cleaning fluids. The waste after cleaning is basically solid powder, small in size, easy to store, recyclable, and can easily solve the environmental pollution problem caused by chemical cleaning;

2. The traditional cleaning method is often contact cleaning, which has mechanical force on the surface of the object to be cleaned. The surface of the object damaged or the cleaning medium attached to the surface of the object to be cleaned cannot be removed, resulting in secondary pollution. The non-abrasive and non-contact nature of laser cleaning makes these problems easy to solve;

3. The laser can be transmitted through optical fiber, cooperated with robot hands and robots to facilitate remote operation, and can clean the parts that are not easy to reach by traditional methods, which can ensure the safety of personnel in some dangerous places;

4. Laser cleaning can remove all kinds of pollutants on the surface of various materials to achieve a cleanliness that cannot be achieved by conventional cleaning. Moreover, the pollutant on the material surface can be selectively cleaned without damaging the material surface;

5. High laser cleaning efficiency and time saving;

6. Although the one-time investment in purchasing the laser cleaning system is high in the early stage, the cleaning system can be used stably for a long time, with low operating cost and only electricity charge per hour.

Compared with traditional cleaning methods such as mechanical friction cleaning, chemical corrosion cleaning, liquid solid strong impact cleaning, high-frequency ultrasonic cleaning, laser cleaning has obvious advantages.

1. Laser cleaning is a "green" cleaning method. It does not need any chemical agents and cleaning fluids. The waste after cleaning is basically solid powder, small in size, easy to store, recyclable, and can easily solve the environmental pollution problem caused by chemical cleaning;

2. The traditional cleaning method is often contact cleaning, which has mechanical force on the surface of the object to be cleaned. The surface of the object damaged or the cleaning medium attached to the surface of the object to be cleaned cannot be removed, resulting in secondary pollution. The non-abrasive and non-contact nature of laser cleaning makes these problems easy to solve;

3. The laser can be transmitted through optical fiber, cooperated with robot hands and robots to facilitate remote operation, and can clean the parts that are not easy to reach by traditional methods, which can ensure the safety of personnel in some dangerous places;

4. Laser cleaning can remove all kinds of pollutants on the surface of various materials to achieve a cleanliness that cannot be achieved by conventional cleaning. Moreover, the pollutant on the material surface can be selectively cleaned without damaging the material surface;

5. High laser cleaning efficiency and time saving;

6. Although the one-time investment in purchasing the laser cleaning system is high in the early stage, the cleaning system can be used stably for a long time, with low operating cost and only electricity charge per hour.