Press release

16

2024,04

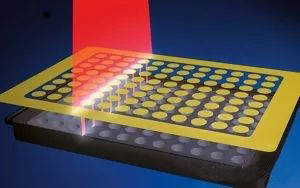

The application of lasers in battery separators cutting

A battery separator refers to a layer of separator material between the positive and negative electrodes of a battery, which is a crucial part of the battery and has a direct impact on the safety and cost of the battery.

More

03

2024,04

Introduction to Plastic Laser Welding Technology

With the energy of laser produces to melt the contact surface of plastics, and then weld the thermoplastic sheet, film and molded components together.

More

26

2024,03

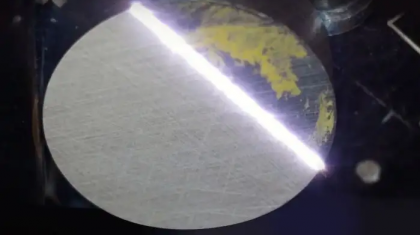

Revitalizing Metals - Laser Rust Removal Technology

Laser rust cleaning is a common application of laser cleaning, with the laser through the rusty metal shell, rust will be quickly taken off, the metal material become smooth and new. But how done this?

If you are going to know how laser achieved to clean the rust, firstly we have to know how metals rust.

More

18

2024,03

The increasing use of ultraviolet lasers in the processing of brittle materials

Laser processing technology involves the physical interaction between the high energy of laser and materials, which vaporizes, ablates, and modifies the materials to achieve material processing effects.

More

08

2024,03

The application of ultrafast laser in aircraft engines

Ultrafast laser technology is an advanced technology that generates high-intensity light pulses in an extremely short period of time

More

01

2024,03

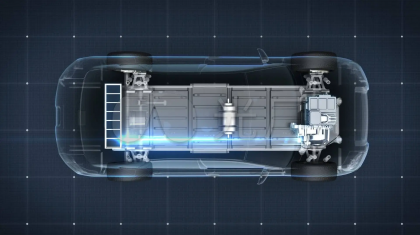

Application of Laser Technology in Power Battery Processing

Due to the increasing complexity of battery production, the number of scratches generated during the production process has increased. These scratches have caused the area around the tank mouth to become dirty, reducing the welding quality of the top cover. Initially, one company SDI used cotton with cleaner to clean these scratches, but the low efficiency forced them to seek other more efficient ways. Laser cleaning, due to its efficient and environmentally friendly advantages, was used by the company SDI to clean all scratches around the shell and remove other unnecessary materials.

It is reported that the company SDI is continuing to develop its fifth generation battery production process. So far, Z-type stacking and label welding have been applied in production, and laser technology is also planned to be applied to the cutting process of battery cells to improve the yield rate of batteries.

More