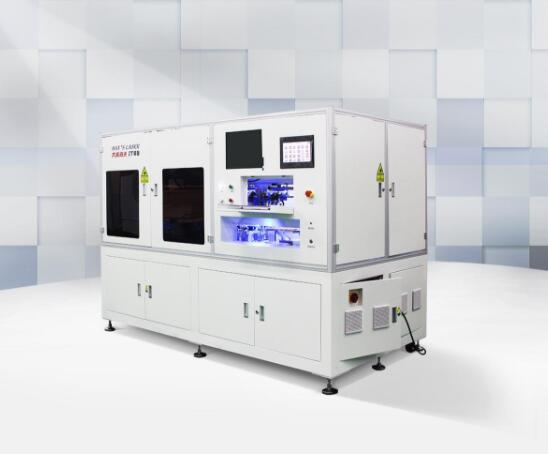

Products Series

Products

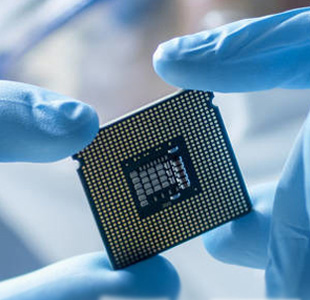

Applications

About Us

HAN'S LASER INTRODUCTION

Han's Laser Technology Industry Group Co., Ltd, a public company which was established in 1996, has now became the flagship of Chinese national laser industry and the world's famous laser equipment manufacturer.

More>

2486

Patent

10746

Professional

500000

Research